Drive Train Development

My introduction to Vintage Bentley was through the ‘Big Bentleys’, the 6½ and 8 Litre cars. I have always admired the 3 Litre and 4½ Litre models, but there is something altogether otherworldly about the larger-engined cars. Perhaps it is their success at Le Mans, the mythology surrounding the Bentley Boys and the Speed Six, or the sheer presence of the 8 Litre machines. Whatever first drew me to them, one requirement was non-negotiable: YF 2186 had to drive flawlessly.

The engine and transmission were the absolute priority. If one examines the invoices and the recorded time invested in the project, almost 3,400 hours in total, it is clear where the major expenditure lies. The largest proportion was directed at the engine and transmission, followed closely by the dashboard and its original instruments. Cosmetics, however beautifully executed, would always remain secondary to mechanical integrity.

When I acquired YF 2186, the accompanying history file demonstrated that the previous owner had used the car extensively on tours and rallies, and had maintained it with considerable care. Between 2010 and 2016 alone, more than £110,000 had been invested. This included a major engine rebuild with the installation of a D-type gearbox in 2012, a new crankshaft and crankcase conversion in 2013, and a replacement radiator in the same year. On paper, the car lacked for nothing.

Nevertheless, as the body restoration progressed and the project evolved, we made the deliberate decision to inspect every mechanical component regardless. Engine, gearbox, brakes, axles and steering were all assessed in detail. The overall verdict was that the car was good, but not exceptional. Good was not sufficient.

This Bentley had to be capable of covering significant distances reliably and without drama. No excuses. I was clear that David Ayre was the right person to rebuild and refine every mechanical system to the highest standard. Together we took the decision to proceed properly, and to do so without compromise.

Mechanical strategy

The mechanical philosophy was straightforward and agreed at the outset.

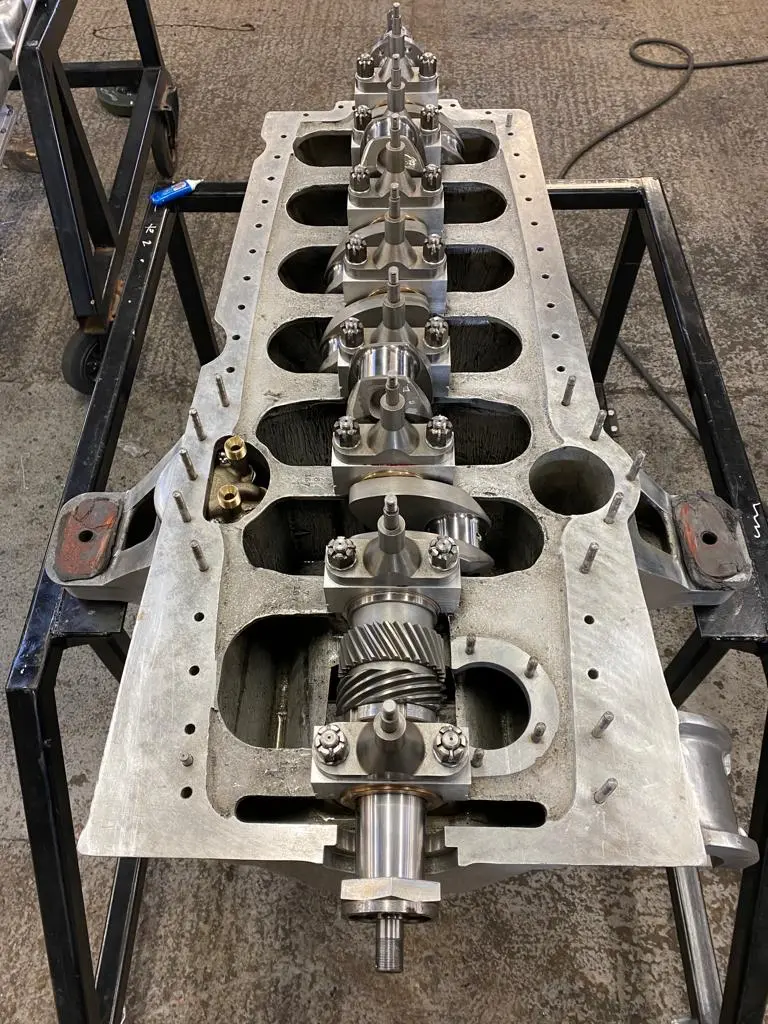

First, we would commission a new cylinder block and preserve the original unit supplied with the car. The intention was to protect and rest the original block rather than subject it to further stress. It has since been carefully stored in its own crate, complete and ready for refitting should it ever be required.

Second, despite the relatively recent expenditure recorded in the history file, we would undertake a complete rebuild of the engine, gearbox and axles. Nothing would be assumed. Every assembly would be stripped, inspected and rebuilt to the highest standard.

Third, where a sensible and sympathetic upgrade existed, we would adopt it. Equally, wherever original components could be retained without compromising reliability or strength, they would be restored, preserved and reused.

Engine Specification

In practical terms, this resulted in the following engine specification:

- New 8 Litre cylinder block

- New 6½ Litre cam chest

- New crankshaft and connecting rod set

- New set of forged pistons

- New rocker box set

- White metal bearings to the six-cylinder main shells

Beyond the major components, considerable time was devoted to rebuilding and correctly specifying the ancillary equipment. This included careful restoration and sourcing of correct-period items such as the Autovac fuel system, magneto, and both four-way and six-way fuse boxes, among many other details.

The cumulative effect is not simply a rebuilt engine, but a fully re-engineered powertrain built to deliver sustained reliability. The objective was clear from the beginning: a Big Bentley that could be driven hard and driven far, with complete confidence.

Gearbox

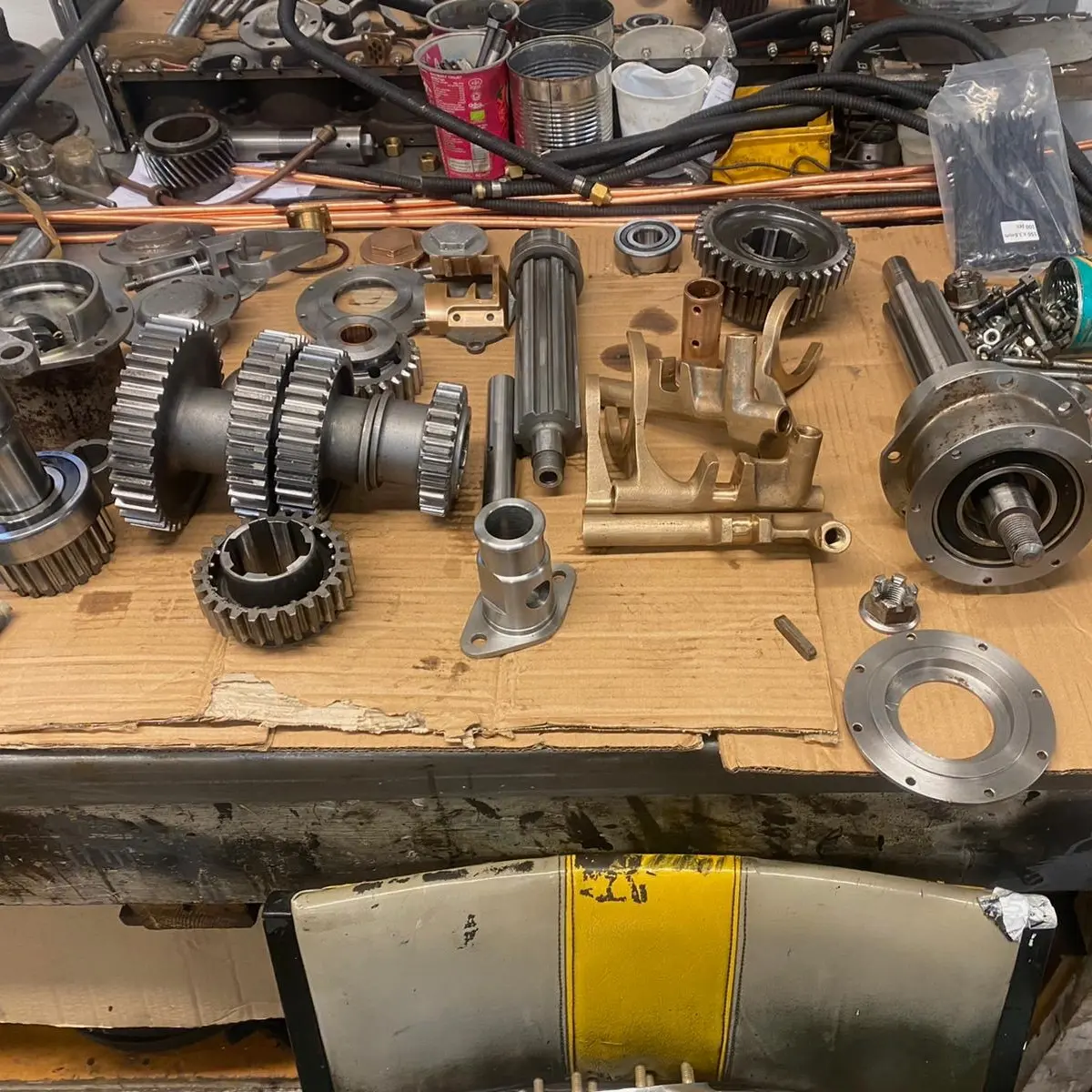

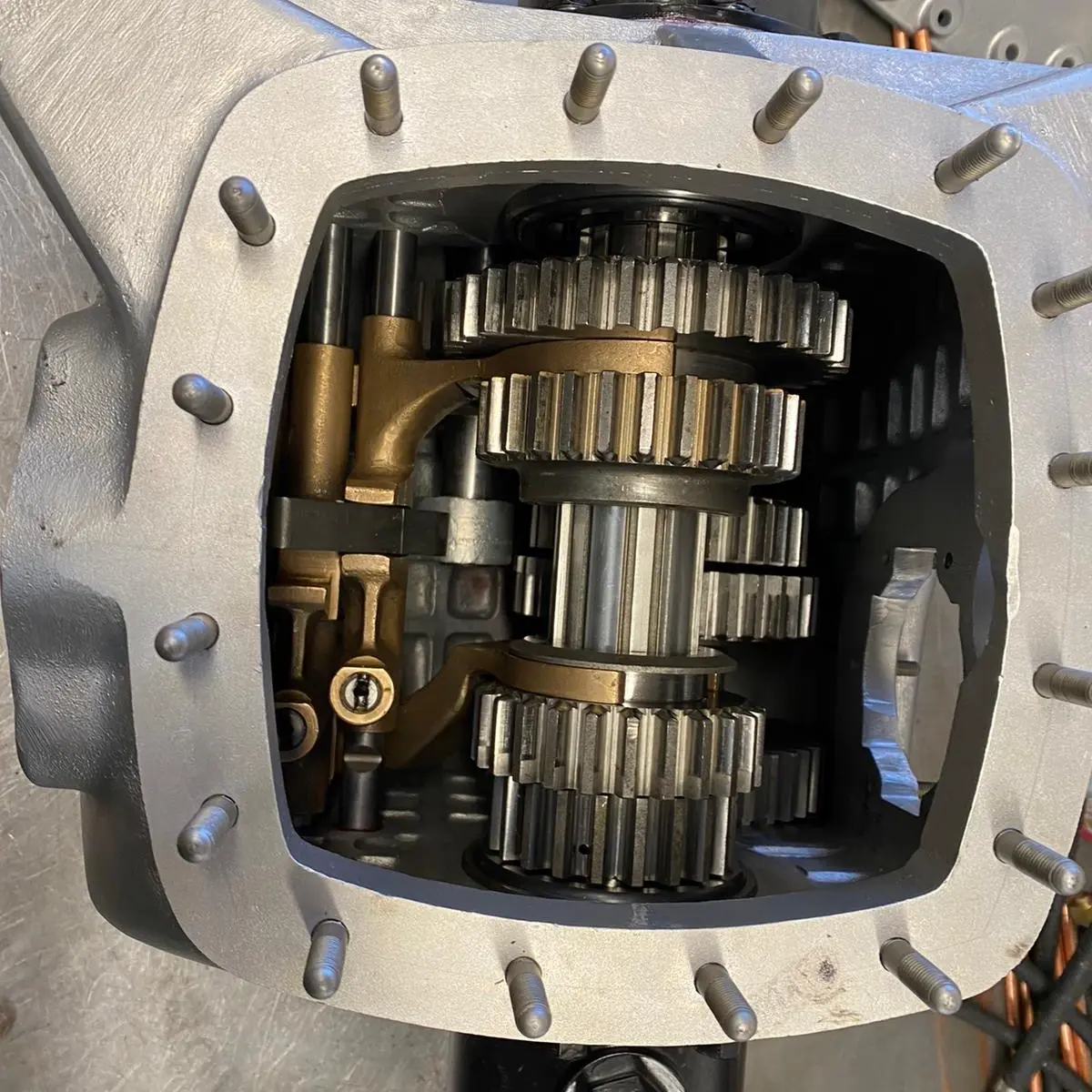

Although a new D-type gearbox had been fitted to YF 2186 in 2012, we took the view that it should nevertheless be removed, stripped and rebuilt as part of the wider mechanical programme.

The decision was consistent with our overall approach. No assumptions were made and no component was left unchecked. The gearbox was fully dismantled, inspected and rebuilt to the same exacting standard as the engine and differential, ensuring correct tolerances, proper gear engagement and long-term reliability.

If the objective was to create a Big Bentley capable of covering serious mileage without concern, then the transmission had to be beyond question.

To install this Web App in your iPhone/iPad press

![]() and then Add to Home Screen.

and then Add to Home Screen.